Tooth shape selection for bimetal Band saw blades

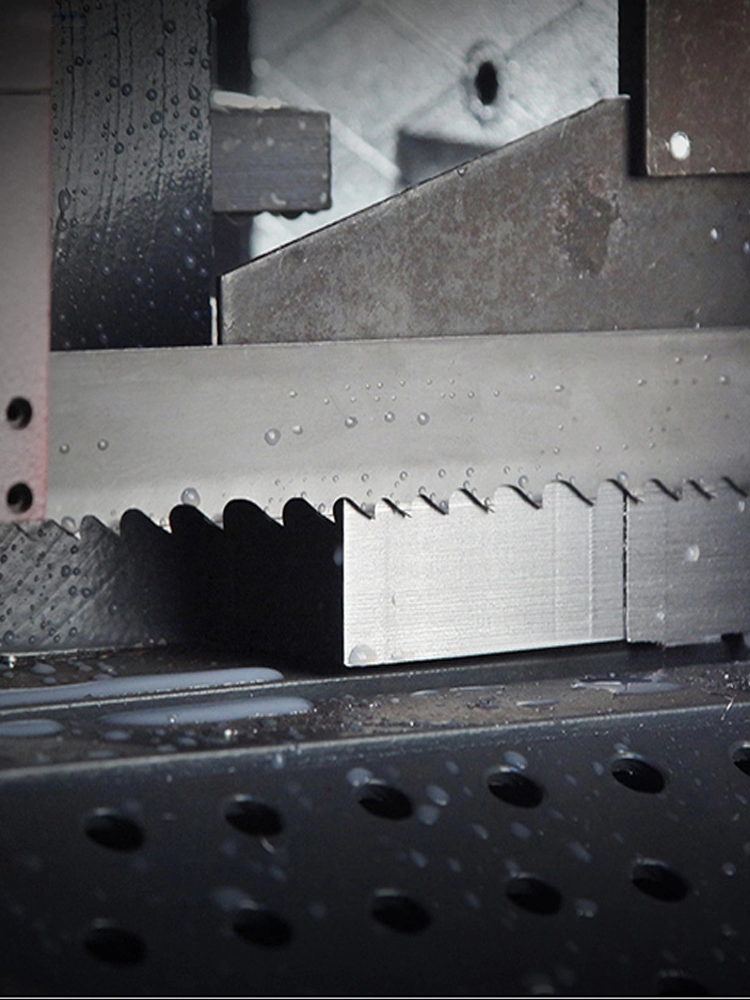

Tooth components:

1. Tooth pitch: that is, the distance between two adjacent teeth.

2. Number of teeth per unit length: that is, the number of complete teeth per 1inch length.

3. Variable pitch: a set of sawtooth cycles with different pitches, represented by the combination of the number of teeth with the maximum pitch and the number of teeth with the minimum pitch per unit length of 1inch. For example, 6/10 variable pitch means that the maximum tooth pitch is 6 teeth within 1inch, and the minimum tooth pitch is 10 teeth within 1inch.

4. Cutting edge: the front edge used for cutting, which is formed by the intersection of the front and back.

5. Tooth slot: the chip-holding space bounded by the front face of the saw tooth, the tooth bottom arc and the back face,

6. Tooth height: the distance from the top of the tooth to the lowest part of the alveolus.

7. The arc radius of the tooth bottom is the arc radius connecting the front of the saw tooth and the back of the previous saw tooth.

8. Base plane:the plane passing through the selected point on the cutting edge and perpendicular to the back edge.

9. Rake angle:the angle between the front surface of the saw tooth and the base surface when the teeth are finally divided into teeth.

10. Wedge angle:the angle between the front and back of the saw tooth when the teeth are divided at the end.

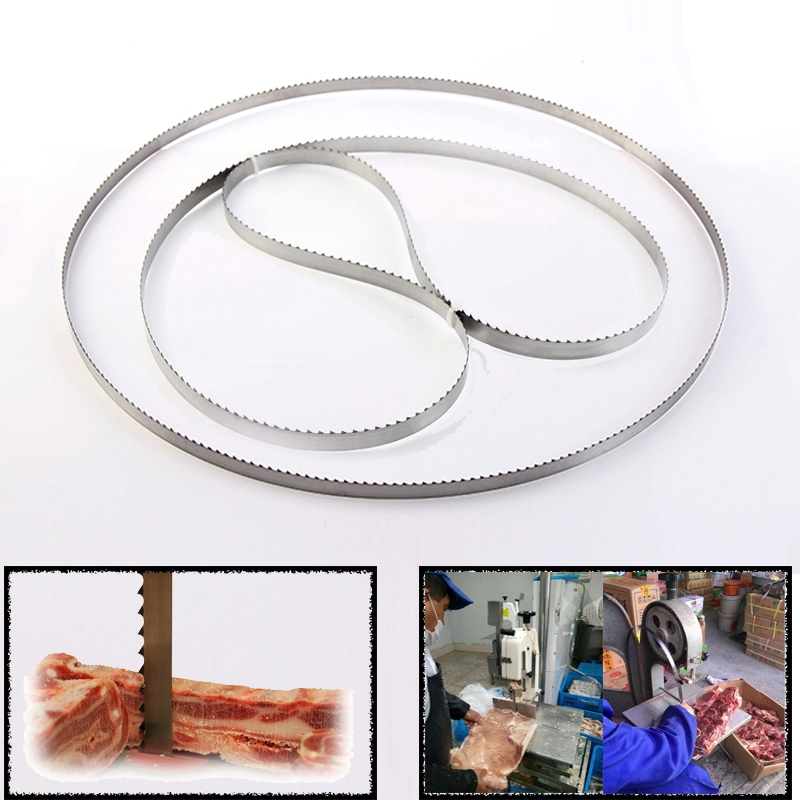

There are many kinds of tooth shapes of bimetal band saw blades. The tooth shapes of the band saw blades used in different specifications and materials are different. Here are some commonly used band saw blade tooth shapes:

Standard teeth: It is a universal tooth shape that can meet the needs of cutting solid materials and thin-walled tubes of different materials. Large cutting angle, strong cutting ability and high versatility.

Tensile teeth: As its name suggests, its main function is to resist tension. The protective steps at the rear corners can prevent excessive cutting. Mainly used for sawing hollow materials and thin-walled materials, such as pipe fittings, special-shaped parts, etc. Deeper tooth grooves provide more space and allow for rapid chip removal.

Turtle back teeth: good structural strength, but relatively large cutting resistance, suitable for sawing into bundles, tubes, profiles, etc.;