How to choose bimetal Band saw blade

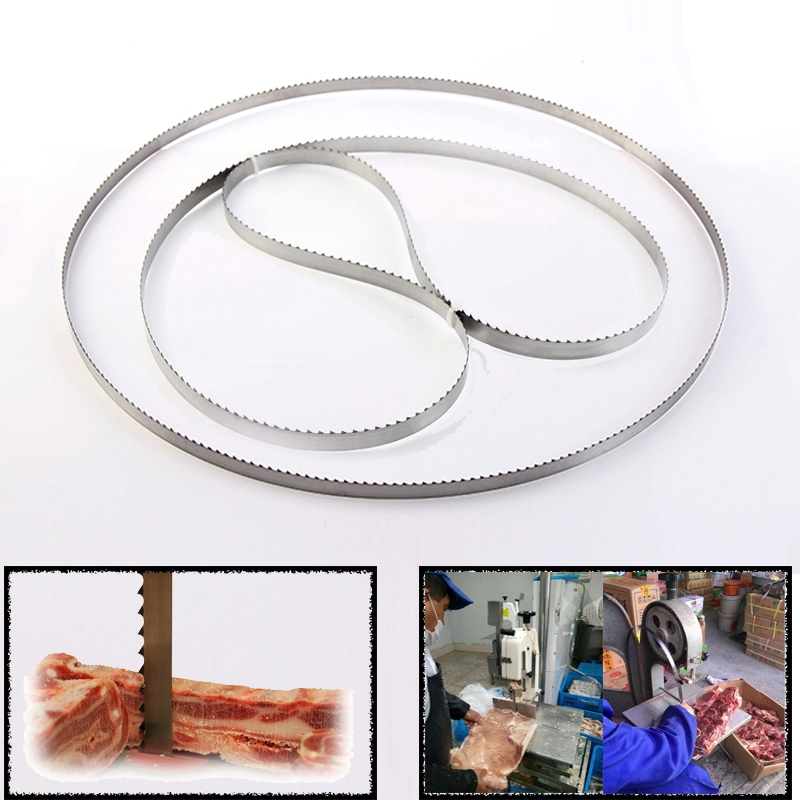

Band saw blades are becoming more and more widely used. Sawing tools represented by bi-metal band saw blades are essential cutting tools in automobile manufacturing, steel metallurgy, large forging, aerospace, nuclear power and other manufacturing fields. However, many buyers often don’t know how to choose when purchasing band saw blades. Now we will tell you in detail how to choose bi metal band saw blades:

1. Select saw blade specifications.

The band saw blade specifications we often refer to the width, thickness, and length of the band saw blade.

Common widths and thicknesses of bi-metal band saw blades are:

13*0.65mm

19*0.9mm

27*0.9mm

34*1.1mm

41*1.3mm

54*1.6mm

67*1.6mm

The length of the band saw blade is usually determined according to the saw machine used. Therefore, when choosing the specifications of a band saw blade, you must first know the length and width of the saw blade used by your sawing machine.

2. Select the angle and tooth shape of the band saw blade.

Different materials have different cutting difficulties. Some materials are hard, some are sticky, and different characteristics have different requirements for the angle of the band saw blade. According to the different tooth shapes of the cutting materials, they are divided into: standard teeth, tensile teeth, turtle teeth and double relief teeth, etc.

Standard teeth are suitable for most common metal materials. Such as structural steel, carbon steel, ordinary alloy steel, cast iron, etc.

Tensile teeth are suitable for hollow and irregular-shaped materials. Such as thin-walled profiles, I-beams, etc.

Turtle back teeth are suitable for cutting large-sized special-shaped profiles and soft materials. Such as aluminum, copper, alloy copper, etc.

The double back angle teeth have significant cutting effect when processing large-sized thick-walled pipes.

3. Select the tooth pitch of the band saw blade.

It is important to select the appropriate tooth pitch of the band saw blade according to the size of the material. It is necessary to understand the size of the material to be sawed. For large materials, large teeth must be used to prevent the saw teeth from being too dense and the iron sharpener cannot row out the teeth. For small materials, it is best to use smaller teeth to avoid the cutting force borne by the saw teeth. is too big.

The tooth pitch is subdivided into 8/12, 6/10, 5/8, 4/6, 3/4, 2/3, 1.4/2, 1/1.5, 0.75/1.25. For materials of different sizes, select appropriate tooth pitches to achieve better sawing results. For example:

The processing material is 45# round steel with a diameter of 150-180mm

It is recommended to choose a band saw blade with a tooth pitch of 3/4.

The processing material is mold steel with a diameter of 200-400mm

It is recommended to choose a band saw blade with a tooth pitch of 2/3.

The processing material is stainless steel pipe with outer diameter of 120mm and wall thickness of 1.5mm, single cutting.

It is recommended to choose a band saw blade with a pitch of 8/12.