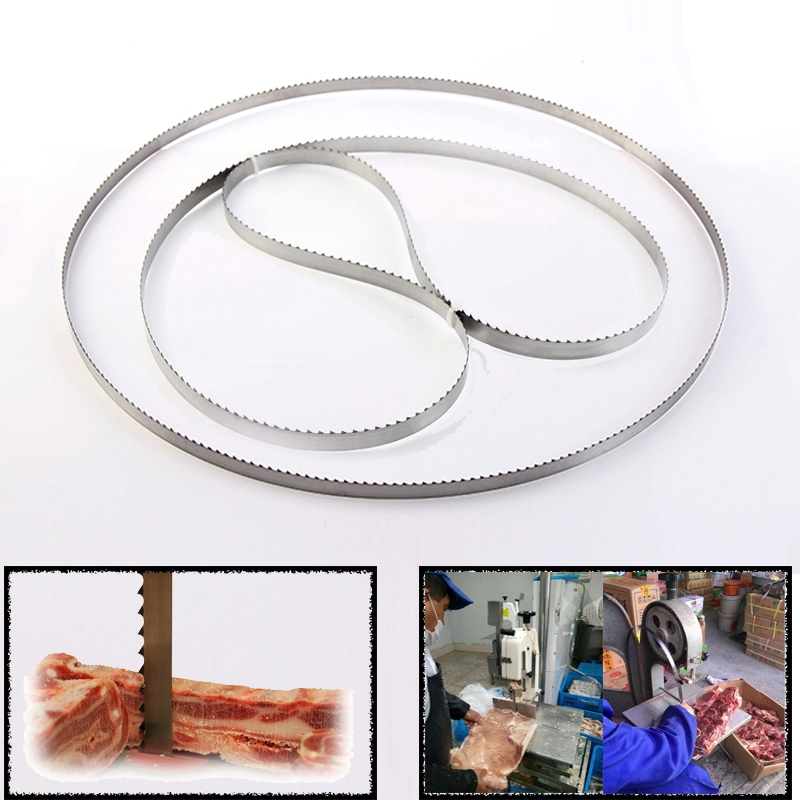

1. Insimbi engagqwali inezici zepulasitiki ezinkulu, ukuqina okuphezulu, namandla ashisayo aphezulu, futhi inokuthambekela okungathi sína ekusebenzeni ukuqina, okudinga izinga eliphakeme lama-Band saw blades.

2. I-saw blade kufanele ibe nokumelana nokushisa okungcono nokumelana nokugqoka okuphezulu. I-bimetallic band saw blades evamile esetshenziselwa ukusaha izinto zensimbi ye-carbon ayifanele ukucubungula izinto zensimbi engagqwali, futhi ama-saha amabhande angagugi kakhulu futhi amelana nokusika kufanele akhethwe ukuze kuzuzwe imiphumela egculisayo yokusaha.

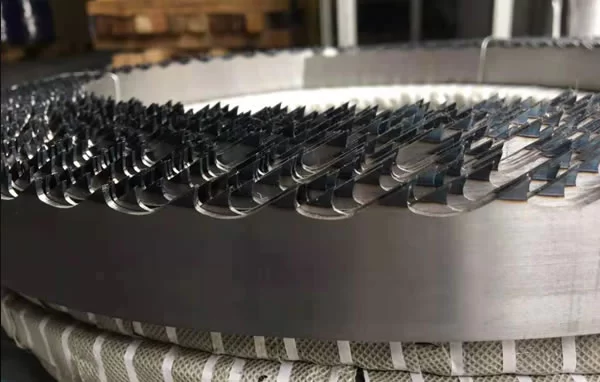

3. Ukuqina namandla ensimbi engagqwali akuphakeme. Ukuqina kwezinto ezivamile zensimbi engu-304, 316, 316L cishe ku-20-25HRC. Kodwa-ke, ukuthungwa kwensimbi engagqwali kuthambile futhi ku-viscous, ama-chips akulula ukukhishwa ngesikhathi sokusika, futhi kulula ukunamathela emazinyweni e-saha ukuze enze ukusika kwesibili, ukuze ukugqoka kwamazinyo e-saw blade kuzokwanda. , futhi i-saha blade ijwayele ukugqoka. Lapho usaha izinto zensimbi engagqwali, ingcindezi yokuphakelayo esetshenzisiwe inkulu kune-carbon steel, futhi ijubane le-band saw blade lihamba kancane. Leli iphuzu lokunakwa okukhethekile. Ijubane lokuzungezisa licishe libe ngu-25-35 m/min lifaneleka kakhulu, futhi alikwazi ukudlula u-40 m/min kakhulu. Uma kungenjalo, ijubane lishesha kakhulu ukuze kubangele ukuthi i-incision yakhe isibuko, futhi ama-serration ebusweni obushelelezi futhi aqinile akulula ukusika, okuzokwandisa ubunzima bokusika.

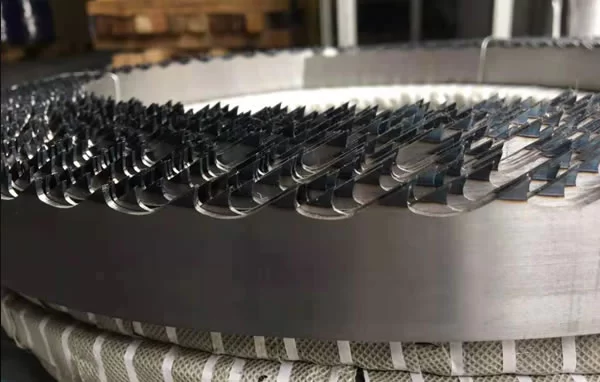

4, naka ukukhetha band wabona izinyo shape

Uma ukhetha iphrofayili yezinyo ye-band saw blade, naka ukukhetha iphrofayili yezinyo nge-engeli enkulu ye-rake. Lokhu akukwazi nje ukunciphisa ukuguqulwa kwepulasitiki kwe-workpiece, kodwa futhi kunciphise amandla okusika kanye nezinga lokushisa lokusika, futhi kunciphise ukujula kwesendlalelo esiqinile.