1. Insimbi engenasici ineempawu zeplastiki enkulu, ukuqina okuphezulu, kunye namandla aphezulu e-thermal, kwaye inotyekelo olunzima lokusebenza ukuqina, okudinga umgangatho ophezulu wee-saw blades.

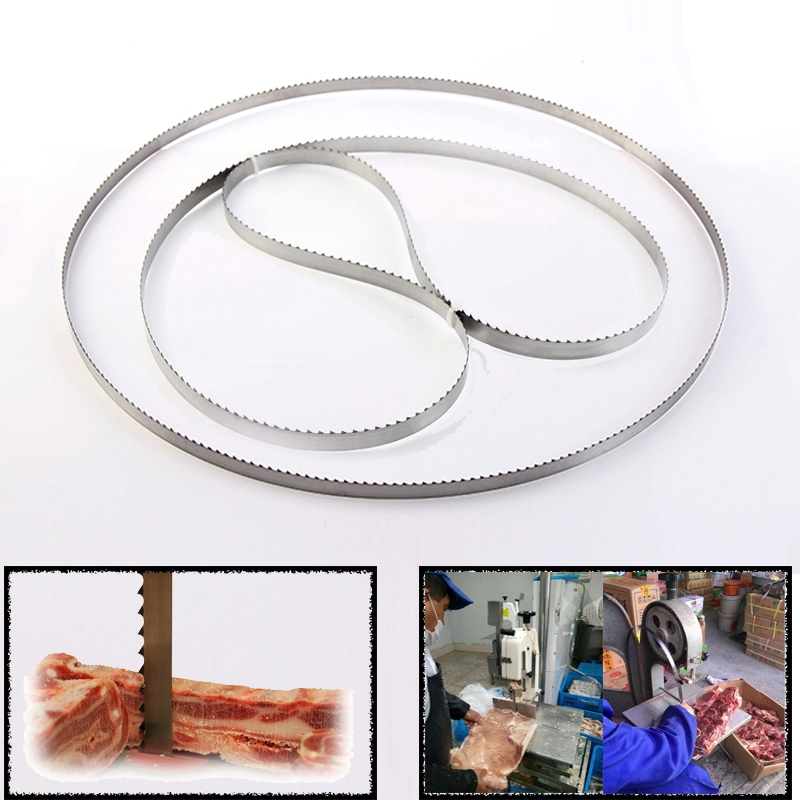

2. I-saw blade kufuneka ibe nokuchasana kobushushu obungcono kunye nokumelana nokugqoka okuphezulu. I-bimetallic band eqhelekileyo yabona ii-blades ezisetyenziselwa ukukhangela izinto zentsimbi zekhabhoni azifanelekanga ukusetyenzwa kwezixhobo zensimbi ezingenasici, kunye ne-band-resistant and cutting-resistant saw blades kufuneka zikhethwe ukuze kuphunyezwe iziphumo ezanelisayo.

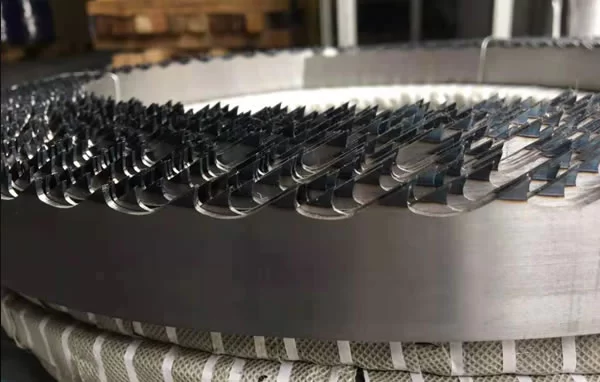

3. Ubunzima kunye namandla ensimbi engenasici ayiphezulu. Ubunzima bezinto eziqhelekileyo ze-304, 316, 316L zensimbi ezingenasici malunga ne-20-25HRC. Nangona kunjalo, ukuthungwa kwensimbi engenasici kuthambile kwaye i-viscous, ii-chips akulula ukuba zikhutshwe ngexesha lokusika, kwaye kulula ukunamathela kumazinyo e-sawha ukwenza ukusika okwesibini, ukwenzela ukuba ukunxiba kwamazinyo e-saw blade kuya kwanda. , kwaye isarha ithande ukunxitywa. Xa ubona izinto zensimbi ezingenasici, uxinzelelo lwesondlo olusetyenzisiweyo lukhulu kunolo lwentsimbi ye-carbon, kwaye isantya se-Band saw blade siyacotha. Le ngongoma yengqalelo ekhethekileyo. Isantya sokujikeleza malunga ne-25-35 m / min yeyona nto ifanelekileyo, kwaye ayikwazi ukudlula i-40 m / min kakhulu. Ngaphandle koko, isantya sikhawuleza kakhulu ukubangela ukuba i-incision yenze i-mirror effect, kwaye i-serrations kwindawo egudileyo kunye neyinkimbinkimbi yezinto eziphathekayo ayilula ukuyinqumla, eya kwandisa ubunzima bokusika.

4, ingqalelo ukukhetha band wabona imilo yezinyo

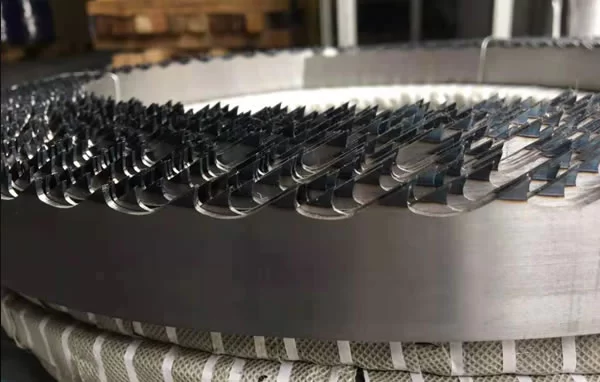

Xa ukhetha iprofayili yezinyo ye-band saw blade, nikela ingqalelo ekukhetheni iprofayili yezinyo nge-angle enkulu yerake. Oku akukwazi ukunciphisa kuphela i-deformation yeplastiki ye-workpiece, kodwa nokunciphisa amandla okusika kunye nobushushu bokusika, kunye nokunciphisa ubunzulu bomgangatho onzima.