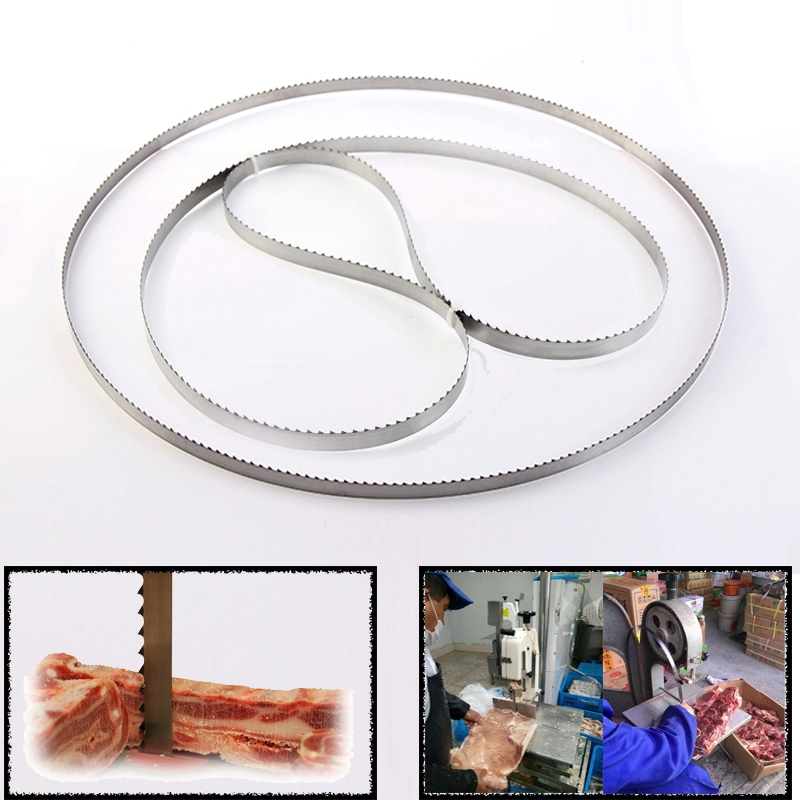

1. Stainless steel has the characteristics of large plasticity, high toughness, and high thermal strength, and has a serious tendency to work hardening, which requires higher quality of Band saw blades.

2. The saw blade should have better heat resistance and high wear resistance. Ordinary bimetallic band saw blades used for sawing carbon steel materials are not suitable for processing stainless steel materials, and more wear-resistant and cutting-resistant band saw blades should be selected to achieve satisfactory sawing results.

3. The hardness and strength of stainless steel are not high. The hardness of common 304, 316, 316L stainless steel materials is about 20-25HRC. However, the texture of stainless steel is soft and viscous, the chips are not easy to be discharged during cutting, and it is easy to adhere to the saw teeth to form a secondary cutting, so that the wear of the saw blade teeth will increase, and the saw blade is more prone to wear. When sawing stainless steel materials, the applied feed pressure is greater than that of carbon steel, and the speed of the band saw blade is slower. This is a point of special attention. Rotation speed is about 25-35 m/min is the most suitable, and it cannot exceed 40 m/min at most. Otherwise, the speed is too fast to cause the incision to form a mirror effect, and the serrations on the smooth and hard material surface are not easy to cut, which will increase the cutting difficulty.

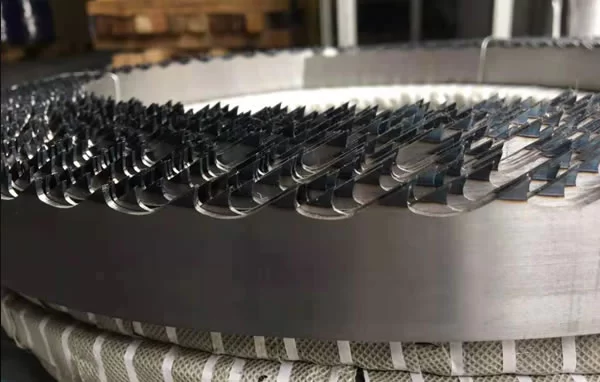

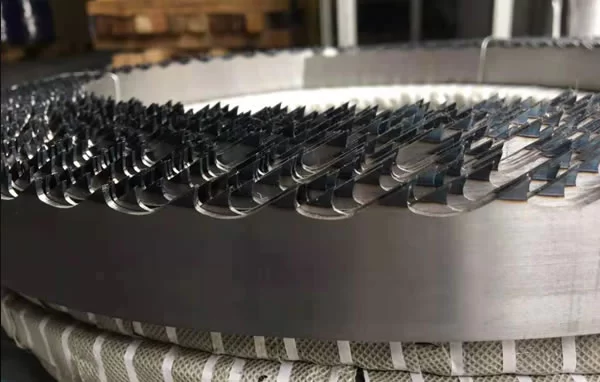

4, pay attention to choose the band saw tooth shape

When selecting the tooth profile of the band saw blade, pay attention to selecting the tooth profile with a large rake angle. This can not only reduce the plastic deformation of the workpiece, but also reduce the cutting force and cutting temperature, and reduce the depth of the hardened layer.